Partners

Good Luck Engineering

Good Luck Engineering forms part of the listed Good Luck Group, who are successfully operating in the area of cold rolling of flat products, tube and pipe production, trading and infrastructure since more than 25 years.

The company is based in Ghaziabad near the Indian capital New Delhi and manufactures standard flanges as well as forgings according to customer drawings from ½" – 60".

With regards to materials grades Good Luck is focussing on austenitic stainless steel and duplex, but also forges martensitic steels (1.4021, 1.4057, etc), alloy and carbon steels.

Next to the chemical, petrochemical and paper industry Good Luck is especially focused in manufacturing flanges and forgings for measuring equipment, fittings / valves and the dairy industries.

Good Luck installed both, open die as well as closed die forging. Furthermore they dispose of an ultramodern CNC machinery park for further processing of the forged parts.

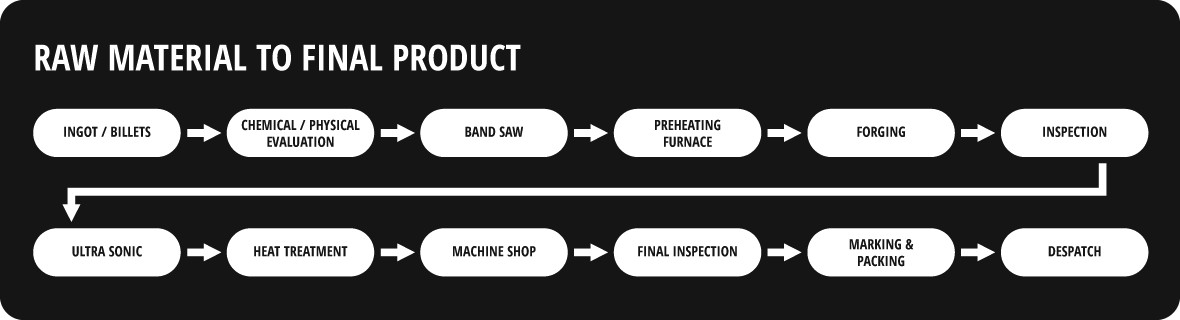

The flow chart right from the pre-material to the finished product is as follows:

Good Luck Engineering Co. is an approved supplier according to AD 2000 WO und PED 97/23/EC (TÜV Rheinland) and runs a quality management system according to DIN ISO 9001. Furthermore the mill is certified according to ISO 14001 (environment) and OHSAS 18001 (secure working environment and conditions).

Website: www.goodlucksteel.com